SAFETY PRECAUTIONS

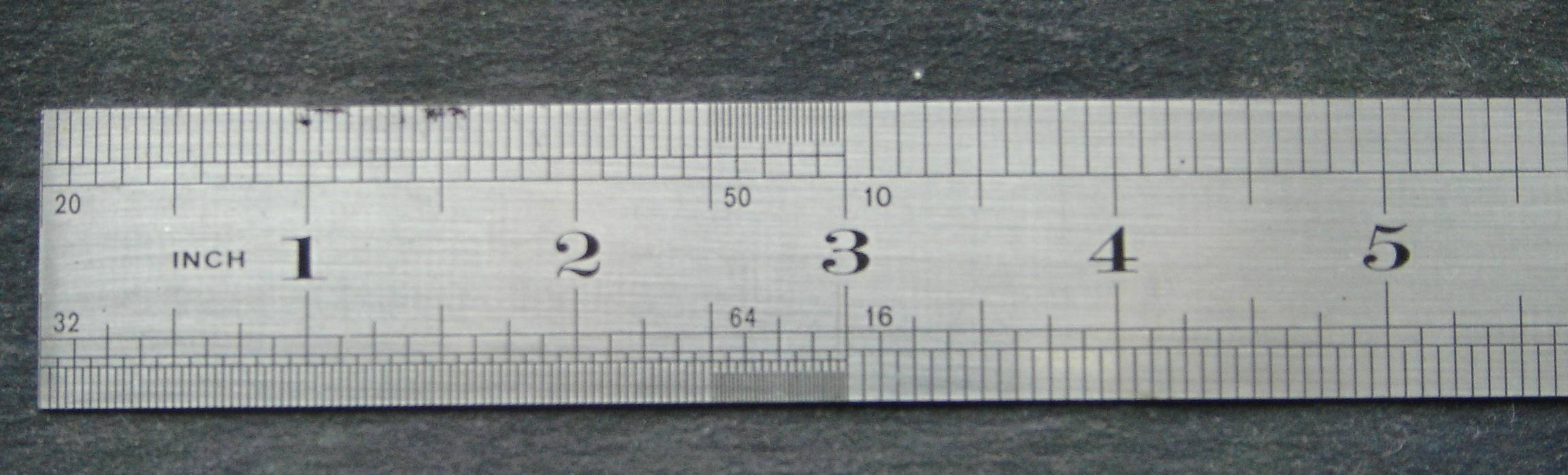

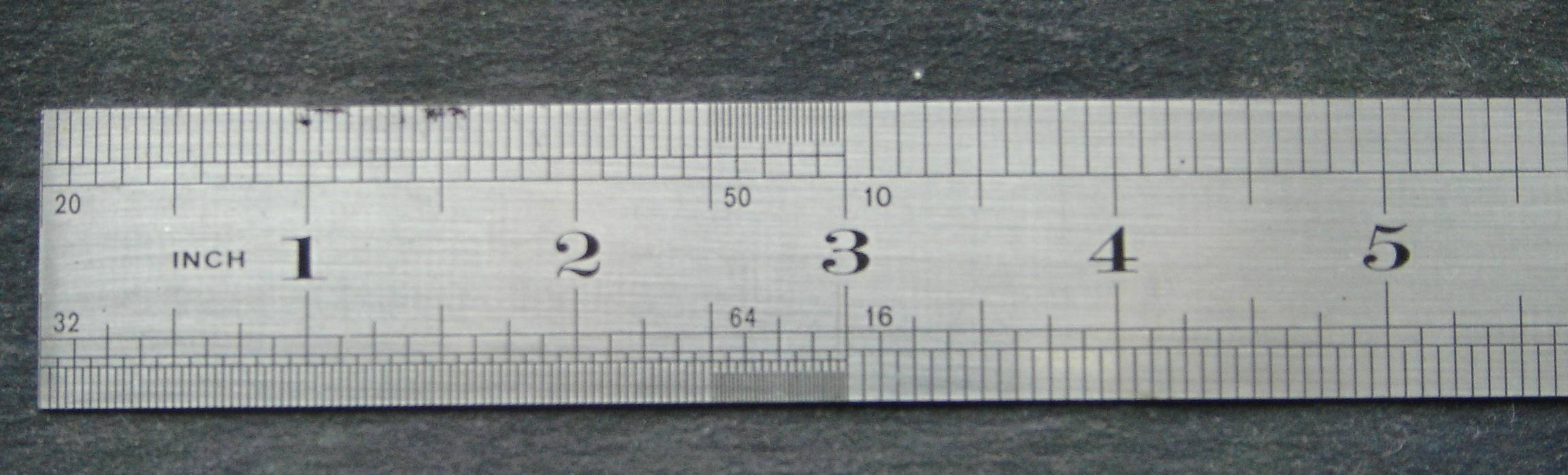

STEEL RULESThe simplest and most common linear measuring instrument is the steel rule shown in fig.1

steel rules are made of spring steel or stainless steel. Lines, called graduations are

inscribed on the face of the rule. Metric rules usually have two sets of line graduations.

Steel rules are available in different lengths, the common sizes being 1.50 mm, 300 mm,

500 mm, and 1000 mm.

MICROMETER

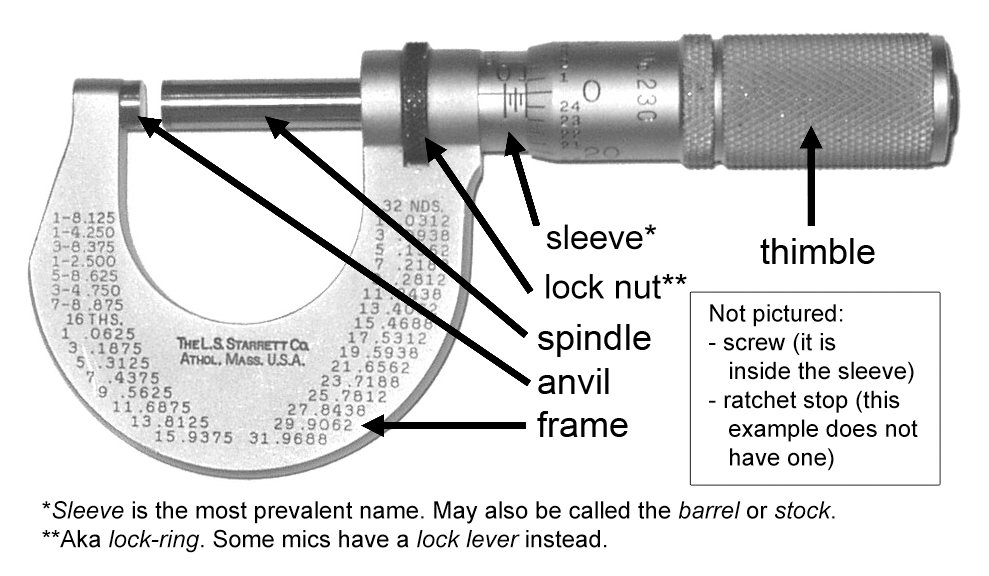

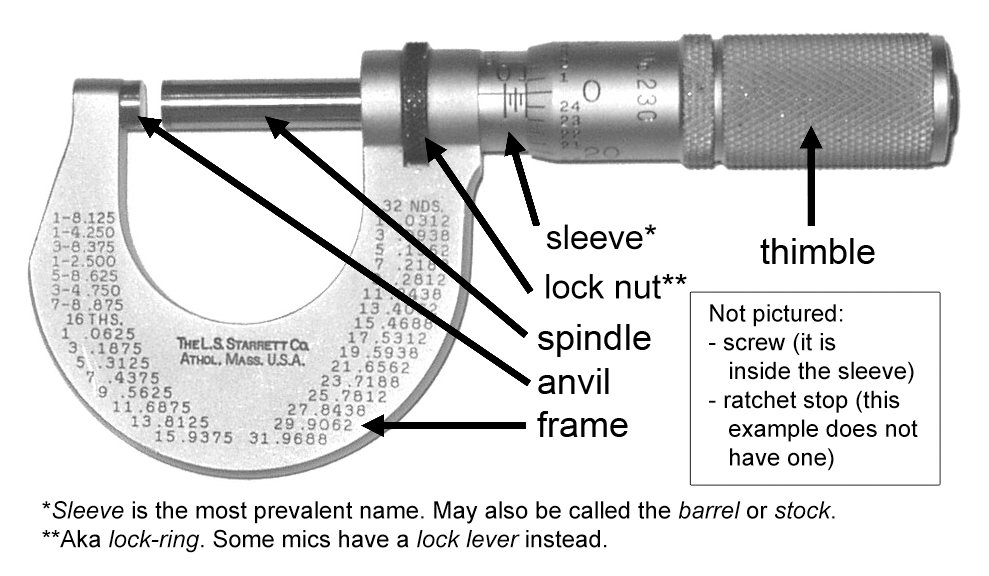

Micrometer or micrometer caliper is one of the most widely used measuring

instruments. Micrometer operates on the principle that an accurate screw will advance the

spindle a precise amount for each revolution. It consists of a fixed anvil and a movable

spindle. The graduated thimble rotates with the spindle and travels along a graduated

sleeve fixed to the frame. The graduations conform to the pitch of the micrometer screw.

To control the pressure between the anvil, the spindle, and the workpiece being measured,

it is equipped with a ratchet or a friction device. Many micrometers are provided with a spindle lock.

Rotating the lock nut in one direction locks the spindle from turning. Micrometer calipers

are available with a variety of specially shaped anvils and spindles.

The metric micrometer has a spindle screw thread with a pitch of 0.5 mm. with one

complete revolution of the screw, the contact face at the end of the spindle either moves

away iron or toward the face of the anvil exactly 0.5 mm. The upper set of graduation on

the sleeve represents whole millimeters and the lowers set divides each millimeter into two

equal parts or 0.5mm, The beveled edge of the thimble is graduated into 50 parts, each

graduation representing l/50 of 0.5mm or 0.01 mm. The micrometer reading is established

by adding the following three values.

|

| Fig 2 |

(i) The last whole number of millimeters that is visible in the top row near the thimble (A)

(ii) The half-millimeter graduation in the lower row (B).

(iii) The graduation on the thimble that coincides with index line (c)

Micrometer reading in mm = A + B x 0.5 + C x 0.01

Referring to fig. 2, the whole number of a millimeter that is visible in the top row is

7, the half-millimeter graduation after 7 in the lower row is 1, and the 18th thimble

graduation is coinciding with the index line,

Micrometer reading in mm = 7 +1 x 0.5 + 1.8 x 0.01= 7.58mm

VERNIER CALIPER

The vernier caliper illustrated in fig. 3 is an end-measuring instrument available in

various sizes that can be used to make both external and internal measurements to an

accuracy of 0.02 mm. It consists of a beam carrying the main scale, inside and outside and

outside measuring jaws, a depth gauge bar, and an adjustable vernier head, which can be

moved along the beam. For fine adjustment, an auxiliary head with a micrometer screw is

provided. Both the heads are provided with locking screws to lock them firmly at any

desired position. The graduated beam of tn. metric vernier caliper is divided into

centimeters and millimeters. The 49 divisions (49 mm) of 1mm each on the beam (main

scale) are equal to 50 divisions of the vernier scale. Thus one division on the vernier equals

49/50mm. The least count of the instrument, i.e., the difference between a division on the main

scale and division on the vernier is

= 1 – 49 / 50 = 1/50mm or 0.02mm. The vernier caliper reading is established by adding

the following two values.

(i) The number of main scale divisions to the left of the 0 on the vernier scale A.

(ii) The line number B on the vernier scale, which is aligned with a line on the beam

(main scale)

Vernier caliper reading = A x Length of 1 main scale division + B x least count

|

| Fig 3. |

the number of divisions on beam left of the 0 one the vernier is 19

and the 22nd line on the vernier scale is aligned with a line on the beam.

.. Vernier caliper reading = 19 x 1 + 22 x 0.02 = 19.44 mm

VERNIER HEIGHT GAUGE

The vernier height gauge is widely used in layout work and for height measurement

up to an accuracy of 0.02mm. It is generally used on a surface plate. The three main parts

of the height gauge are the base, the column, and the slide arm. The main scale is on the

column and the vernier scale is attached to the slide arm. A flat scriber is secured to the

slide arm for layout work as shown in fig 4

|

| Fig 4. |

BEVEL PROTRACTORThe bevel protractor shown in fig.5 is used for measurement jor layout of angles.

The protractor has a head with a revolving turret graduated to 900

degrees on each side of

zero. A vernier is provided to measure the angle accurately. The head is adjustable along a

tempered blade

|

| Fig 5. |

Thank you